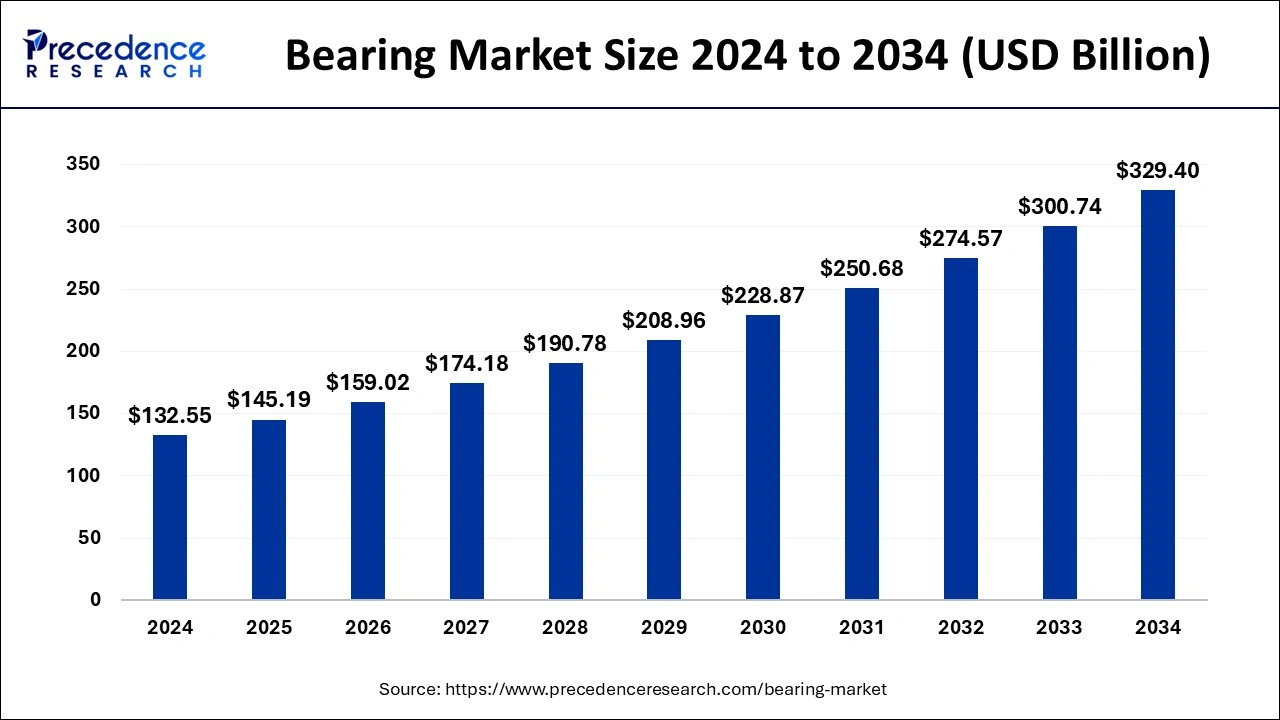

The bearing market at USD 132.55B in 2024, is projected to hit USD 329.40B by 2034, growing at a 9.53% CAGR.

Bearing Market Key Takeaways

- With a 41% share, Asia Pacific dominated the market in 2024.

- Roller bearings emerged as the top product segment in 2024.

- The automotive sector captured the largest application share in 2024.

- Strong growth is anticipated in railway and aerospace applications during the forecast period.

The bearing market, valued at USD 132.55 billion in 2024, is expected to grow to USD 329.40 billion by 2034 at a 9.53% CAGR. Asia Pacific dominates with 41% of the market share due to industrial and automotive growth. Roller bearings hold the largest product share, with the automotive sector leading in applications. Railway and aerospace industries show strong potential for expansion during the forecast period, as innovations in transportation drive demand for advanced bearings.

Sample Link: https://www.precedenceresearch.com/sample/1020

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 329.40 Billion |

| Market Size in 2025 | USD 145.19 Billion |

| Market Size in 2024 | USD 132.55 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 9.53% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Type, Material, Distribution Channels, Size, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Key Drivers

Increasing demand for food and beverages due to population and income growth has led to investments in food processing equipment, with bearings being vital for enhancing efficiency and safety. Food-grade stainless steel ball bearings are widely used in food machinery. In the medical sector, miniature bearings are crucial for precision tools and devices, meeting stringent requirements like low friction, minimal noise, and high durability. These advancements are driving growth in the bearing market.

Opportunities

- Increased adoption of bearings in wind turbine components like shafts and generators.

- Demand for advanced bearing technologies to enhance turbine efficiency and reduce energy loss.

- Innovation in asymmetric spherical roller bearings for better power transmission in wind turbines.

- Expansion of renewable energy driving the need for dynamic and durable bearing solutions.

- Custom-designed bearings tailored to optimize wind turbine performance and effectiveness.

Challenges

- Precision engineering demands for turbine bearings lead to increased production costs.

- Bearings are prone to damage from fluctuating environmental factors, such as temperature and moisture.

- Continuous improvements and innovations in bearing design require substantial time and resources.

- The limited lifespan of bearings in wind turbines creates maintenance and replacement challenges.

- Difficulty in balancing lightweight designs with high load-bearing capacities for turbine efficiency.

Regional Insights

Asia Pacific leads the global bearing market, driven by the expansion of machinery and vehicle manufacturing in China, Japan, and India. The region is predicted to grow at a 9.66% CAGR from 2025 to 2034. North America’s market is bolstered by increased car production, with demand rising for lightweight bearings to meet stringent environmental regulations. Europe is witnessing growth due to the rising production of electric and hybrid vehicles. Emerging economies like South Africa and Brazil show high growth potential, while mature markets like Western Europe and Japan are supported by strong investments and vehicle production recovery.

Don’t Miss Out: Femtech Market

Market Key Players

- NSK Ltd

- Schaeffler AG

- RBC Bearings Incorporated

- JTEKT Corporation

- NTN Bearing Corporation

- Danaher

Recent News

In October 2024, Ormat Technologies Inc. launched the Plain Bearings Turbine (PBT), featuring hydrodynamic bearings designed to exceed the lifespan of standard geothermal plant components while boosting power capacity. During the same month, SKF Automotive introduced the Hub Bearing Unit (HBU) wheel bearing, a lightweight innovation with 10% less weight and 30% reduced friction, combining two rolling bearings in a single unit to enhance automotive efficiency.

Market Segmentation

By Product Type

- Plain Bearing

- Ball Bearing

- Four-point Contact

- Self-aligning

- Deep Groove

- Angular Contact

- Others

- Roller Bearing

- Others

By Type

- Mounted Bearing

- Unmounted Bearing

By Material

- Metal

- Stainless Steel

- Chrome Steel

- Carbon Steel

- Brass

- Others

- Plastic

- Ceramic

By Distribution Channel

- OEM

- Aftermarket

By Size

- 30 to 40

- 41 to 50

- 51 to 60

- 61 to 70

- 70 & above

By Application

- Electrical

- Construction

- Aerospace

- Automotive

- Power Transmission

- Oil & Gas