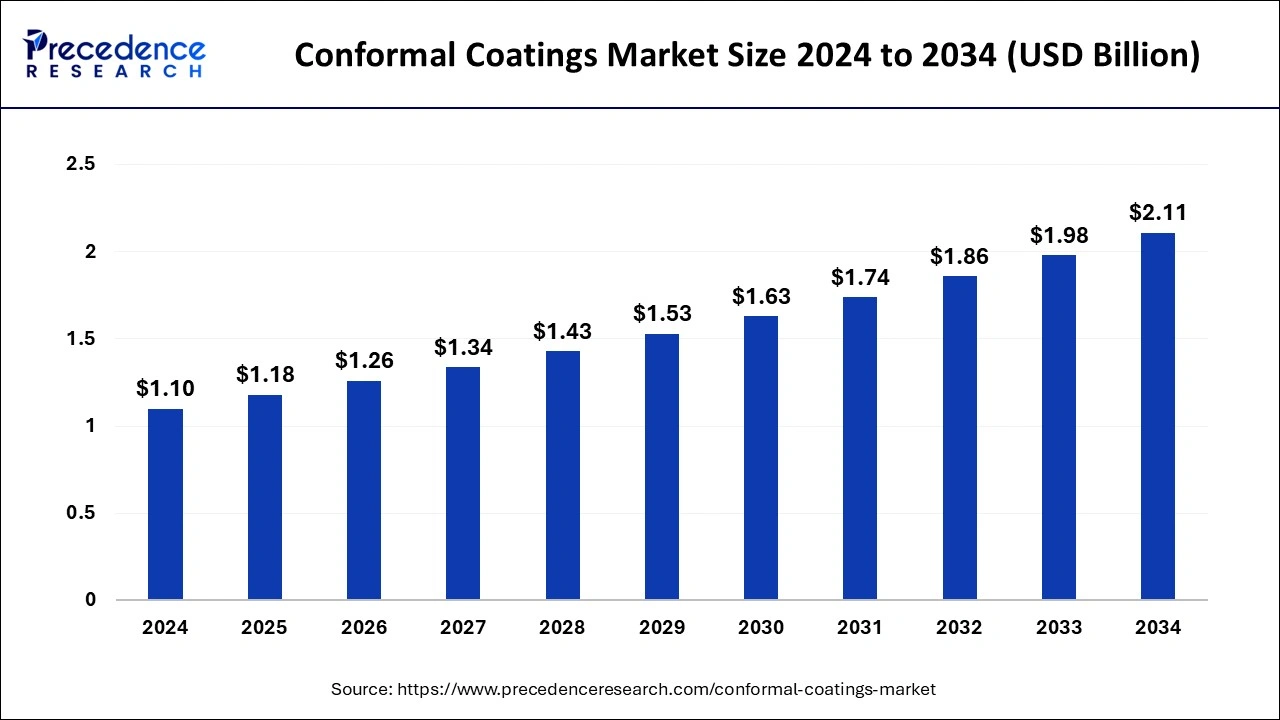

The Conformal coatings market is to grow from USD 1.10B in 2024 to USD 2.11B by 2034, with a CAGR of 6.73%.

Conformal Coatings Market Key Takeaways

- Asia Pacific led the global conformal coatings market in 2023, holding the highest market share of 52%.

- The acrylic segment dominated the global market in 2023, emerging as the leading product category.

- The perylene segment is expected to witness significant growth, expanding at a notable CAGR during the forecast period.

- The consumer electronics segment accounted for the highest market share in 2023, driven by increasing demand for electronic devices.

The conformal coatings market is experiencing steady growth, driven by increasing demand for electronic protection in industries such as automotive, consumer electronics, aerospace, and medical devices. In 2024, the market was valued at USD 1.10 billion and is projected to reach USD 2.11 billion by 2034, growing at a CAGR of 6.73%. Asia Pacific dominates the market, holding the largest share due to rapid industrialization and expanding electronics manufacturing.

Acrylic coatings led the market in 2023, while the perylene segment is expected to grow at a significant rate during the forecast period. The consumer electronics sector remains the largest end-user segment, fueled by the rising adoption of advanced electronic devices and the increasing need for circuit protection.

Sample Link: https://www.precedenceresearch.com/sample/1102

Key Drivers

Opportunities

- Growing demand for conformal coatings in the automotive and aerospace industries to enhance electronic component durability.

- Increasing adoption of advanced consumer electronics, driving the need for protective coatings against moisture and contaminants.

- Rising investments in environmentally friendly and UV-curable coating technologies to meet regulatory and sustainability requirements.

- Expanding industrialization in emerging markets, particularly in Asia-Pacific, creating new growth opportunities for manufacturers.

- Technological advancements in nano-coatings and smart coatings offering enhanced protection and extended lifespan for electronic devices.

Challenges

- High costs associated with advanced coating materials and application processes, limiting affordability for small manufacturers.

- Stringent environmental regulations regarding the use of volatile organic compounds (VOCs) in coating formulations.

- Complex application procedures requiring specialized equipment and expertise, increasing operational costs.

- Limited awareness and adoption of newer coating technologies among small and medium-sized enterprises.

- Challenges in ensuring uniform coating application on intricate electronic components, affecting product performance and reliability.

Regional Insights

Asia Pacific leads the conformal coatings market, holding the largest share due to rapid industrialization, growing electronics manufacturing, and increasing demand for protective coatings in automotive and consumer electronics. China, Japan, and South Korea are key contributors, driven by strong production capacities and technological advancements. North America follows closely, supported by high adoption of advanced electronics, stringent regulatory standards, and a well-established aerospace and automotive sector.

Europe also holds a significant market share, driven by increasing investments in eco-friendly coatings and the expansion of the automotive and medical device industries. The Middle East & Africa and Latin America are witnessing steady growth, primarily due to improving industrial infrastructure, rising demand for electronic protection, and growing investments in manufacturing sectors.

Don’t Miss Out: Surface Disinfectant Market

Market Key Players

- Dow

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- ITW

- Shin-Etsu Chemical Co. Ltd

- Chemtronics, KGaA.

- Others

Recent News

Recent developments in the conformal coatings market indicate significant growth and innovation. In September 2024, the market was valued at USD 1.4 billion and is projected to reach USD 1.8 billion by 2028, growing at a CAGR of 5.3%. This expansion is driven by the increasing demand for protective coatings in consumer electronics, automotive, aerospace, and telecommunications sectors. Notably, the automotive conformal coatings segment is expected to reach USD 3.5 billion by 2030, up from USD 2.0 billion in 2024, reflecting a CAGR of 10.0%.

This surge is attributed to the rising integration of electronic components in vehicles and advancements in application methods. Additionally, in April 2020, Dow introduced a solventless silicone conformal coating with dual UV and moisture cure capabilities, enhancing efficiency in high-volume electronics manufacturing. These developments underscore the dynamic and evolving nature of the conformal coatings industry.

Market Segmentation

By Product

- Epoxy

- Acrylic

- Silicone

- Polyurethane

- Parylene

- Fluoropolymer

By Operation Method

- Brush Coating

- Dip Coating

- Spray Coating

- Chemical Vapor Deposition

By End-User

- Automotive

- Consumer Electronics

- Industrial Machinery & Equipment

- Aerospace

- Marine

- Medical

- Defense

- Others

By Technology

- Water-based

- Solvent-based

- UV Cured