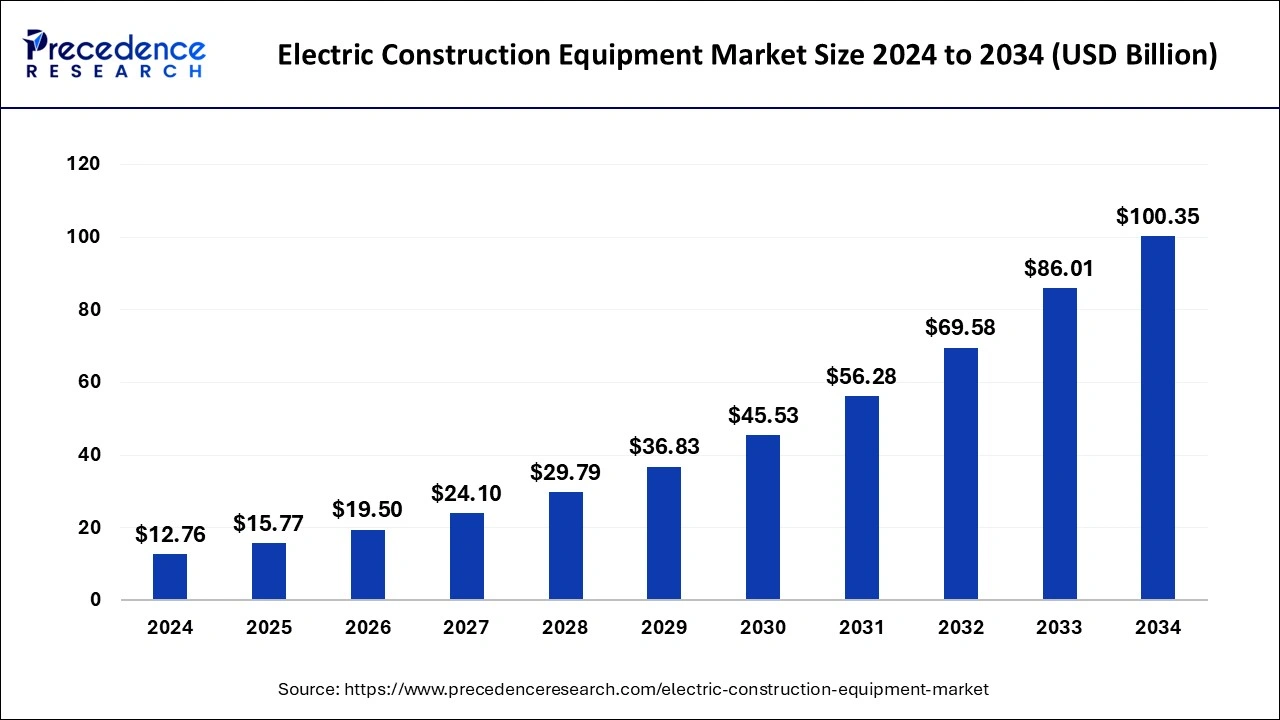

The global electric construction equipment market size is expected to grow around USD 86.01 billion by 2033, growing at a CAGR of 23.62% from 2024 to 2033.

Key Points

- Asia Pacific contributed 34% of market share in 2023.

- North America is estimated to expand the fastest CAGR between 2024 and 2033.

- By vehicles, the excavators segment held the largest market share of 30% in 2023.

- By vehicles, the cranes segment is anticipated to grow at a remarkable CAGR of 25.2% between 2024 and 2033.

- By source, the lithium-ion segment generated over 44% of market share in 2023.

- By source, the lead acid segment is expected to expand at the fastest CAGR over the projected period.

- By end use, the construction segment generated over 32% of market share in 2023.

- By end use, the industrial segment is expected to expand at the fastest CAGR over the projected period.

The electric construction equipment market is witnessing significant growth as the construction industry embraces sustainable practices and seeks to reduce emissions and operating costs. Electric construction equipment, powered by batteries or hybrid systems, offers several advantages over traditional diesel-powered machinery, including lower emissions, reduced noise pollution, and potentially lower operating costs over the equipment’s lifecycle. This market encompasses a wide range of electric construction equipment, including excavators, loaders, bulldozers, cranes, and compactors, catering to various construction applications and project requirements. As governments worldwide implement stricter environmental regulations and initiatives to promote sustainable construction practices, the demand for electric construction equipment is expected to continue rising in the coming years.

Get a Sample: https://www.precedenceresearch.com/sample/4046

Growth Factors

Several key factors are driving the growth of the electric construction equipment market. Firstly, increasing environmental concerns and regulations aimed at reducing carbon emissions and air pollution have incentivized construction companies to adopt electric machinery as part of their sustainability initiatives. Electric construction equipment offers significant reductions in greenhouse gas emissions and air pollutants compared to diesel-powered counterparts, aligning with global efforts to mitigate climate change and improve air quality. Additionally, advancements in battery technology, including higher energy density, faster charging capabilities, and declining costs, have enhanced the feasibility and performance of electric construction equipment, making it increasingly attractive to construction companies seeking to lower their carbon footprint and operating costs.

Region Insights:

The adoption of electric construction equipment varies across regions due to differences in regulatory frameworks, infrastructure development, market maturity, and construction activity levels. Developed regions such as Europe and North America have witnessed significant uptake of electric construction equipment, driven by stringent emissions regulations, government incentives, and a growing emphasis on sustainability in construction practices. Europe, in particular, has been at the forefront of electric construction equipment adoption, with countries like Norway and Sweden leading the transition to electric machinery in construction projects. Emerging markets in Asia-Pacific, including China and India, are also increasingly embracing electric construction equipment, fueled by rapid urbanization, infrastructure development, and government initiatives to promote clean energy technologies.

Trends:

Several trends are shaping the electric construction equipment market. One notable trend is the development of all-electric and hybrid electric construction machinery with advanced features and capabilities to meet the diverse needs of construction projects. Manufacturers are investing in research and development to improve the performance, efficiency, and durability of electric construction equipment while also integrating smart technologies for remote monitoring, predictive maintenance, and energy optimization. Another trend is the collaboration between equipment manufacturers, technology companies, and construction firms to develop innovative solutions and accelerate the adoption of electric construction machinery. Moreover, the growing focus on electrification and sustainability in construction projects, including green building certifications and environmental impact assessments, is driving demand for electric construction equipment worldwide.

Electric Construction Equipment Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 23.62% |

| Global Market Size in 2023 | USD 10.32 Billion |

| Global Market Size in 2024 | USD 12.76 Billion |

| Global Market Size by 2033 | USD 86.01 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Vehicles, By Source, and By End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Electric Construction Equipment Market Dynamics

Drivers:

Several drivers are propelling the adoption of electric construction equipment globally. Firstly, the increasing emphasis on sustainability and environmental stewardship in the construction industry is driving demand for cleaner, low-emission alternatives to traditional diesel-powered machinery. Electric construction equipment offers construction companies an opportunity to reduce their carbon footprint, comply with regulations, and enhance their corporate social responsibility initiatives. Additionally, the total cost of ownership (TCO) of electric construction equipment, including lower fuel and maintenance costs over the equipment’s lifespan, is becoming increasingly competitive with diesel-powered counterparts, especially as battery technology continues to improve and costs decline. Moreover, government incentives, subsidies, and procurement policies aimed at promoting electric vehicles and clean technologies are encouraging construction companies to invest in electric construction equipment and transition away from diesel-powered machinery.

Opportunities:

The electric construction equipment market presents various opportunities for stakeholders across the value chain. Equipment manufacturers have the opportunity to innovate and develop advanced electric machinery that meets the performance, reliability, and durability requirements of construction projects while also offering environmental and economic benefits. Battery manufacturers and suppliers can capitalize on the growing demand for high-performance batteries tailored for construction equipment applications, including fast-charging solutions, high-energy-density batteries, and ruggedized designs suitable for harsh operating environments. Additionally, construction companies and contractors have the opportunity to improve their sustainability credentials, reduce operating costs, and gain a competitive edge by incorporating electric construction equipment into their fleets. Furthermore, governments, regulatory bodies, and industry associations can support the adoption of electric construction equipment through policy incentives, funding programs, and infrastructure investments to accelerate the transition to sustainable construction practices.

Challenges:

Despite the promising growth prospects, the electric construction equipment market faces several challenges that could hinder its widespread adoption. One of the primary challenges is the upfront cost premium associated with electric construction equipment compared to conventional diesel-powered machinery, which may deter some construction companies from investing in electric alternatives, especially in price-sensitive markets. Moreover, concerns about the availability and reliability of charging infrastructure for electric construction equipment, particularly on remote job sites or in regions with limited electrification, pose significant challenges for adoption. Battery technology limitations, including energy density, charging speed, and operating temperature range, also present challenges for manufacturers striving to develop electric construction equipment with comparable performance to diesel-powered counterparts. Additionally, the lack of standardized regulations and certification processes for electric construction equipment, as well as concerns about residual value and resale market dynamics, may inhibit investment decisions and fleet transition strategies for construction companies.

Read Also: Carbon Footprint Management Market Size, Trends, Report by 2033

Recent Developments

- In 2023, Komatsu achieved significant strides in the electric construction equipment sector. Key releases included the PC05E-1 Electric Micro Excavator, offering zero emissions in Europe for their 3-ton mini excavator range. Additionally, Komatsu introduced the PC200LCE-11 and PC210LCE-11 Electric Excavators, their initial large electric models, promising performance comparable to diesel equivalents but with zero emissions. At CONEXPO 2023, they unveiled the HB365LC-3 Hybrid Excavator, enhancing fuel efficiency and reducing emissions by integrating a diesel engine with an electric motor and battery.

- In June 2022, Cummins and Komatsu signed a memorandum of understanding to collaborate on zero-emission haulage equipment development. Komatsu had previously announced a power-agnostic truck concept in 2021, capable of utilizing various power sources such as diesel-electric, trolley, battery power, and hydrogen fuel cells.

- In the same month of June 2022, John Deere announced a global partnership with Wacker Neuson to develop excavators ranging from 0 to 9 metric tons. Wacker Neuson will manufacture excavators under five metric tons, while John Deere will oversee design, manufacturing, and technology innovation for models between 5 to 9 metric tons.

- In May 2022, Volvo Construction Equipment (Volvo CE) made an investment in Dutch firm Limach, specializing in electric excavators for the domestic market. This investment supports Volvo CE’s long-term electrification strategy and expands its electromobility product range.

- March 2022 saw the joint development showcase of the PC01E-1 by Honda and Komatsu. This electric micro excavator, powered by portable and interchangeable mobile batteries, represents Komatsu’s first foray into electric micro excavators, developed in collaboration with Honda.

- In December 2021, Volvo Construction Equipment (Volvo CE) collaborated with partners across the electric ecosystem to deliver a comprehensive site solution for real urban applications. This project involved machine demonstrations in Gothenburg, supported by entities such as Gothenburg City, NCC, Gothenburg Energy, Lindholmen Science Park, Chalmers University of Technology, and ABB Electrification Sweden, with funding from the Swedish Energy Agency.

- In October 2021, Caterpillar Venture Capital Inc. (Caterpillar) and another venture invested USD 16 million in BrightVolt, Inc. BrightVolt Inc. is renowned for designing, developing, and manufacturing safe, high-energy, low-cost solid-state lithium-ion batteries. This funding aims to advance larger form-factor products catering to industrial electrification and e-mobility markets.

Electric Construction Equipment Market Companies

- Volvo Construction Equipment

- Komatsu

- Caterpillar

- John Deere

- Honda

- Cummins

- Wacker Neuson

- XCMG

- Hitachi Construction Machinery

- Liebherr

- JCB

- Doosan Infracore

- Hyundai Construction Equipment

- Kobelco Construction Machinery

- Sany Group

Segments Covered in the Report

By Vehicles

- Excavators

- Loaders

- Cranes

- Others

By Source

- Lithium-Ion

- Lead Acid

- Others

By End-use

- Residential

- Construction

- Industrial

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.dailytechbulletin.com/

Blog: https://www.autoindustrybulletin.com/