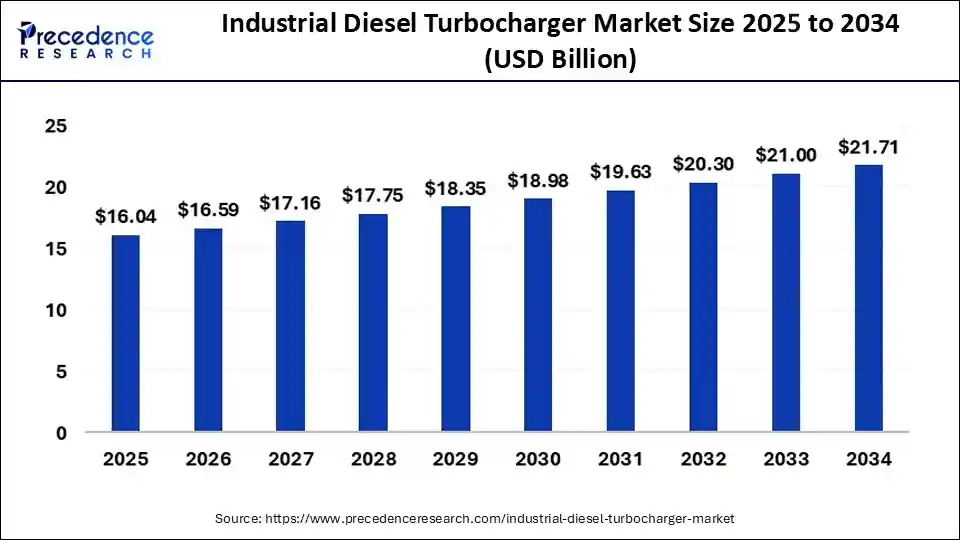

The global industrial diesel turbocharger market was valued at USD 15.51 billion in 2024 and is projected to reach approximately USD 21.71 billion by 2034, growing at a CAGR of 3.42%.

Industrial Diesel Turbocharger Market Key Takeaways

- Asia Pacific dominated the industrial diesel turbocharger market with the largest share of 40% in 2024.

- North America is expected to grow at a significant rate over the forecast period.

- By engine type, the diesel engines segment led the global market in 2024.

- By engine type, the internal combustion engine segment is estimated to grow fastest over the forecast period.

- By sales channel, the OEM sales segment held the largest market share in 2024..

- By sales channel, the direct sales segment is expected to grow at the fastest rate over the forecast period.

- By component type, the compressors segment dominated the market in 2024.

- By component type, the turbine segment is expected to grow rapidly over the projected period.

- By application, the power generation segment dominated the market in 2024.

- By application, the marine application segment is expected to grow at a significant rate over the forecast period.

The industrial diesel turbocharger market is witnessing steady growth, driven by increasing demand for fuel-efficient and high-performance engines across various industrial applications. Turbochargers play a crucial role in enhancing engine efficiency, reducing emissions, and optimizing fuel consumption in diesel-powered machinery used in sectors such as power generation, marine, construction, mining, and transportation. With stringent environmental regulations and the global push toward energy efficiency, industries are adopting advanced turbocharging technologies to improve performance while meeting sustainability standards.

In 2024, the market was valued at approximately USD 15.51 billion and is projected to reach around USD 21.71 billion by 2034, growing at a CAGR of 3.42%. The expansion of industrial infrastructure, coupled with the increasing adoption of heavy-duty diesel engines in manufacturing and logistics, is fueling market growth. Technological advancements, including variable geometry turbochargers (VGT), electric turbochargers, and hybrid turbocharging systems, are transforming the industry, allowing better control over power output and efficiency.

The rising focus on reducing carbon emissions has led to the integration of turbocharger-based emission control systems, further propelling the demand for these components. As governments enforce strict emission norms, industries are investing in next-generation diesel turbochargers that enhance engine performance while minimizing environmental impact.

Sample Link: https://www.precedenceresearch.com/sample/5717

Key Drivers

The growing demand for fuel-efficient diesel engines is a significant factor driving the industrial diesel turbocharger market. Turbochargers help optimize fuel consumption by increasing engine power output without requiring a larger engine size, making them an essential component in sectors such as power generation, construction, marine transport, and mining. With rising fuel prices and the need for cost-effective operations, industries are increasingly adopting turbocharged diesel engines to improve operational efficiency.

Stringent emission regulations worldwide are further accelerating market growth. Governments and regulatory bodies are enforcing stricter emission norms to curb air pollution, prompting industries to adopt advanced turbocharging technologies that help reduce nitrogen oxide (NOx) and carbon dioxide (CO₂) emissions. This trend has driven innovations such as dual-stage turbochargers and electric-assisted turbochargers, which enhance combustion efficiency while meeting environmental standards.

The rapid expansion of the marine and transportation industries is also fueling demand. With the global trade network growing, there is an increasing need for fuel-efficient diesel-powered vessels, freight trains, and heavy-duty trucks. Turbocharged diesel engines offer enhanced torque and power output, making them a preferred choice for transportation applications. Additionally, turbochargers contribute to reducing maintenance costs by improving engine longevity, making them an attractive investment for industrial operators.

Opportunities

The adoption of electric and hybrid turbocharging technologies presents significant growth opportunities. Traditional turbochargers rely on exhaust gases for operation, but the introduction of electric turbochargers eliminates lag, improves response time, and enhances engine efficiency. As industries transition toward hybrid and electric powertrain solutions, the demand for e-turbochargers is expected to rise, opening new avenues for market expansion.

The rise of automation and smart manufacturing is also creating opportunities for advanced turbocharging systems. The integration of IoT-enabled turbochargers with real-time monitoring capabilities allows industries to track engine performance, diagnose issues remotely, and optimize efficiency. Predictive maintenance enabled by AI-driven analytics is becoming a game-changer, helping businesses reduce downtime and operational costs.

Emerging markets in Asia-Pacific, Latin America, and Africa offer untapped potential for industrial diesel turbocharger manufacturers. Rapid industrialization, infrastructure development, and increased investments in power generation, construction, and logistics are driving demand for high-performance diesel engines. As governments in these regions invest in energy-efficient technologies, the adoption of turbochargers is expected to rise.

Challenges

Despite its growth potential, the industrial diesel turbocharger market faces challenges related to supply chain disruptions and fluctuating raw material prices. The production of turbochargers requires high-quality materials such as titanium, stainless steel, and aluminum alloys, and any disruptions in the supply chain can impact manufacturing costs and lead to price fluctuations. The recent volatility in commodity prices and geopolitical tensions has further intensified these challenges.

The increasing shift towards electrification in the automotive and industrial sectors poses another challenge. While diesel engines remain a dominant force in heavy industries, the rising adoption of electric and hydrogen-powered alternatives is gradually impacting the demand for traditional turbochargers. Manufacturers need to innovate and develop hybrid-compatible turbocharging systems to stay relevant in the evolving market landscape.

The complexity of turbocharger maintenance and repair is also a concern. Turbochargers operate under high-temperature and high-pressure conditions, making them susceptible to wear and tear. Regular maintenance and specialized servicing are required to ensure optimal performance, and the lack of skilled professionals in some regions poses a hurdle for widespread adoption.

Regional Insights

North America holds a significant share in the industrial diesel turbocharger market, driven by the strong presence of manufacturing, mining, and construction industries. The United States and Canada have well-established industrial infrastructure, leading to a consistent demand for high-performance diesel engines. The region’s stringent emission regulations have also accelerated the adoption of advanced turbocharger technologies, with key players focusing on fuel-efficient and low-emission solutions.

Europe is another major market, with countries like Germany, the UK, and France investing in energy-efficient industrial machinery. The region’s commitment to sustainability and emission control measures has led to increased adoption of variable geometry turbochargers and hybrid turbocharging systems. The strong presence of automotive and marine engine manufacturers further supports market growth in Europe.

The Asia-Pacific region is witnessing rapid expansion, fueled by industrialization, infrastructure development, and increasing energy demands. Countries like China, India, Japan, and South Korea are heavily investing in power plants, heavy machinery, and commercial transportation, driving demand for turbocharged diesel engines. China, in particular, has emerged as a major manufacturing hub for turbocharger components, contributing to regional growth.

Latin America and the Middle East & Africa are also showing promising growth, with increased investments in oil & gas, mining, and industrial transportation. The demand for high-performance diesel engines in these regions is expected to rise as economies develop and infrastructure projects expand. Governments in these regions are also implementing clean energy policies, encouraging the adoption of low-emission diesel technologies.

Don’t Miss Out: Automotive Heads-up Display Market

Market Key Players

- Cummins

- Turbo Energy

- KTT

- Kangyue

- BorgWarner

- K turbocharger

- Weichai Power

- Mitsubishi Heavy Industries

- IHI Corporation

Recent News

The industrial diesel turbocharger market has seen significant technological advancements in recent years. Companies are focusing on developing next-generation turbochargers that improve fuel efficiency, reduce emissions, and enhance engine performance. The introduction of electric turbochargers and waste heat recovery turbo systems has marked a major step forward in achieving sustainability goals.

Several leading turbocharger manufacturers are investing in strategic collaborations and acquisitions to expand their market presence. Industry giants are partnering with automotive and industrial engine manufacturers to develop customized turbocharging solutions tailored to specific applications. Research & development efforts are intensifying, with a focus on AI-powered turbocharger diagnostics, predictive maintenance solutions, and smart energy management.

The push for alternative fuel engines has also influenced the market, with manufacturers exploring turbocharging solutions for biodiesel, hydrogen, and synthetic fuel-powered engines. These innovations aim to balance performance efficiency with reduced carbon emissions, ensuring long-term sustainability in industrial applications.

The industrial diesel turbocharger market is poised for steady growth, driven by the rising demand for fuel-efficient engines, stricter emission regulations, and rapid industrialization. While challenges such as raw material costs, market shifts toward electrification, and maintenance complexities persist, advancements in hybrid turbocharging, electric turbo systems, and smart diagnostics are shaping the future of the industry. As industries continue to prioritize energy efficiency and sustainability, the demand for next-generation turbochargers is expected to remain strong, ensuring long-term market expansion.

Market Segmentation

By Engine Type

- Internal Combustion Engine

- Diesel Engine

- Natural Gas Engine

- Dual Fuel Engine

- Heavy Fuel Engine

By Component Type

- Bearing Systems

- Compressor

- Turbine

- Wastegate

- Actuators

By Application

- Marine

- Power Generation

- Construction Equipment

- Mining

- Agricultural Equipment

By Sales Channel

- Direct Sales

- Distributor Sales

- Online Sales

- OEM Sales

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa