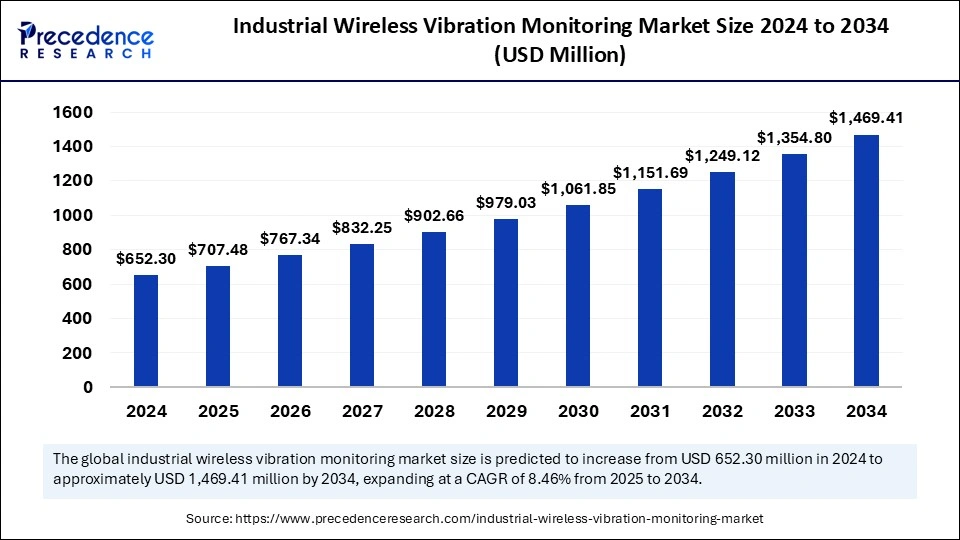

The global industrial wireless vibration monitoring market is expected to grow from USD 652.30 million in 2024 to approximately USD 1,469.41 million by 2034, registering a CAGR of 8.46%.

Industrial Wireless Vibration Monitoring Market Key Takeaways

- North America dominated the market by holding 36% of market share in 2024.

- Europe is expected to witness the fastest growth in the coming years.

- By type, the wireless sensors segment held the biggest market share of 37% in 2024.

- By type, the data acquisition systems segment is projected to grow at the fastest rate during the forecast period.

- By application, the condition monitoring segment contributed the highest market share of 42% in 2024.

- By application, the predictive maintenance segment is anticipated to grow rapidly during the projection period.

Key Drivers

Several key factors are fueling the growth of the industrial wireless vibration monitoring market

- Rising Demand for Predictive Maintenance – Industries are shifting from reactive to predictive maintenance strategies to reduce equipment failure, minimize downtime, and optimize asset performance.

- Growth of Industry 4.0 & Smart Factories – The adoption of automation, IoT, and AI in industrial settings is driving demand for wireless vibration monitoring solutions that integrate with smart manufacturing systems.

- Cost-Effectiveness & Scalability – Wireless systems eliminate the need for complex wiring, making installation easier and reducing overall maintenance costs, particularly in large-scale industrial operations.

- Increasing Industrial Safety Regulations – Governments and regulatory bodies are enforcing stringent safety and reliability standards, encouraging industries to implement advanced monitoring solutions.

- Expanding Use in Harsh & Remote Environments – Wireless vibration monitoring is becoming essential in industries such as oil & gas, mining, and offshore operations, where remote monitoring is critical for operational efficiency and safety.

Opportunities

The industrial wireless vibration monitoring market presents several opportunities for expansion and innovation

- Integration with AI & Machine Learning – The use of AI-driven analytics can enhance predictive maintenance by detecting anomalies and forecasting failures before they occur.

- Adoption in Emerging Economies – Developing markets in Asia-Pacific and Latin America are embracing industrial automation, creating a growing demand for wireless monitoring solutions.

- Cloud-Based & Edge Computing Solutions – The integration of wireless monitoring with cloud platforms and edge computing enables real-time data processing and faster decision-making.

- Development of Battery-Powered & Energy-Efficient Sensors – Innovations in low-power and self-sustaining sensors can further improve the efficiency and longevity of wireless monitoring systems.

- Expansion into Non-Traditional Industries – Sectors such as healthcare, automotive, and food processing are exploring the benefits of wireless vibration monitoring for equipment reliability and efficiency.

Challenges

Despite its advantages, the industrial wireless vibration monitoring market faces some challenges

- High Initial Investment – The cost of deploying wireless sensors, data processing infrastructure, and integration with existing systems can be a barrier for small and mid-sized enterprises.

- Connectivity & Data Security Concerns – Wireless systems are susceptible to signal interference and cybersecurity threats, requiring robust encryption and secure data transmission protocols.

- Limited Awareness & Adoption in Traditional Industries – Some industries still rely on conventional wired monitoring systems due to lack of awareness about the benefits of wireless solutions.

- Scalability Issues in Large Industrial Plants – Deploying and managing thousands of wireless sensors in large-scale manufacturing facilities requires advanced network infrastructure and data management capabilities.

- Battery Life & Power Supply Limitations – Wireless sensors often require battery replacements, which can add maintenance costs and create challenges in remote industrial locations.

Regional Insights

- North America – Leading the market due to widespread adoption of Industry 4.0, strong investments in automation, and the presence of key market players in the U.S. and Canada. The oil & gas and aerospace industries are major drivers.

- Europe – Countries like Germany, the UK, and France are rapidly implementing wireless vibration monitoring solutions to enhance industrial efficiency and comply with stringent safety regulations.

- Asia-Pacific – The fastest-growing region, driven by industrial expansion, increasing adoption of smart manufacturing, and government initiatives promoting automation in countries like China, India, and Japan.

- Latin America & Middle East & Africa – Emerging markets are gradually adopting wireless monitoring solutions, particularly in mining, oil & gas, and infrastructure development projects.

Don’t Miss Out: Autonomous Mobile Robots Market

Market Key Players

- GE Vernova

- Honeywell

- Siemens

- Fluke Corporation

- SKF Group

Recent News

- Advancements in Sensor Technology – Companies are launching next-generation wireless vibration sensors with improved battery life, real-time analytics, and enhanced connectivity.

- Strategic Partnerships & Acquisitions – Major players in the industry are acquiring startups and forming alliances to expand their product offerings and market reach.

- Government & Industry Regulations – New regulations on workplace safety and equipment reliability are driving increased adoption of wireless vibration monitoring solutions.

- Expansion of Cloud-Based Monitoring Solutions – The integration of wireless sensors with cloud-based platforms is enabling remote monitoring and predictive maintenance across multiple industrial sites.

The industrial wireless vibration monitoring market is poised for strong growth as industries continue to embrace digital transformation, predictive maintenance, and automation. With ongoing technological advancements and increasing awareness of operational efficiency benefits, the market is expected to expand significantly in the coming years.

Market Segmentation

By Type

- Wireless Sensors

- Wireless Controllers

- Vibration Transmitters

- Data Acquisition Systems

- Vibration Analysis Software

By Application

- Condition Monitoring

- Asset Management

- Predictive Maintenance

- Machine Health

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa (MEA)