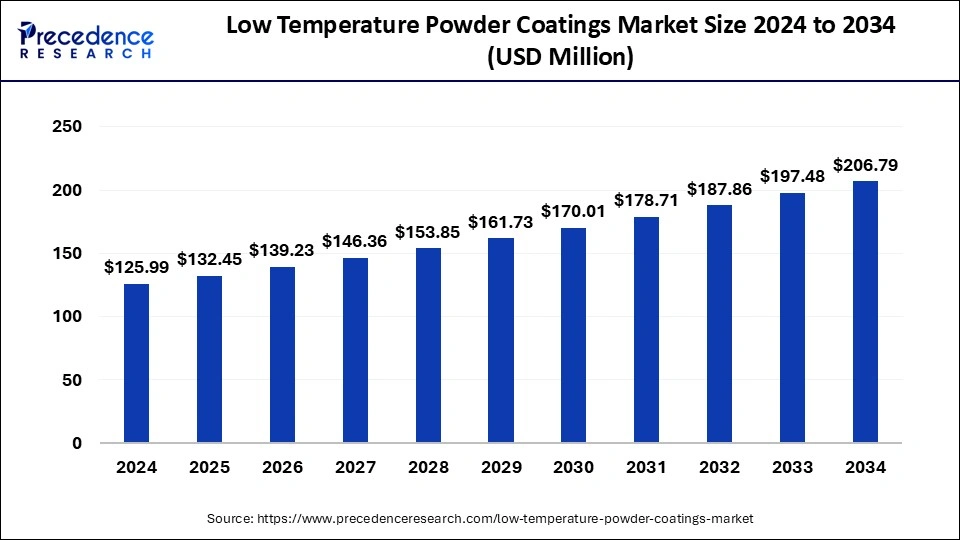

The global low temperature powder coatings market size was valued at USD 119.86 million in 2023 and is predicted to reach around USD 197.48 million by 2033, expanding at a CAGR of 5.12% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market with the largest revenue share of 35% in 2023.

- By resin type, the polyester segment held the largest share of the market in 2023.

- By resin type, the epoxy segment is expected to be the fastest growing in the market during the forecast period.

- By substrate type, the metal segment has held the biggest revenue share of 42% in 2023.

- By substrate type, the steel segment is expected to be the fastest growing segment over the predicted timeframe.

- By end use, the automotive segment held the significant share of the market in 2023.

Low temperature powder coatings have gained significant attention in recent years due to their environmental benefits and versatility in various industrial applications. These coatings are applied in a powder form and cured at lower temperatures than traditional powder coatings, offering advantages such as reduced energy consumption and enhanced substrate compatibility. The market for low temperature powder coatings is driven by increasing environmental regulations, growing demand for eco-friendly coating solutions, and expanding applications across industries like automotive, appliances, furniture, and construction.

Get a Sample: https://www.precedenceresearch.com/sample/4505

Growth Factors

The low temperature powder coatings market is poised for robust growth due to several key factors. Firstly, stringent environmental regulations worldwide have accelerated the adoption of eco-friendly coating technologies. Low temperature powder coatings, which emit lower volatile organic compounds (VOCs) during application and curing, align with these regulations, driving their demand among manufacturers looking to comply with environmental standards. Additionally, advancements in powder coating technology have improved the performance characteristics of low temperature variants, making them more attractive for high-performance applications.

Moreover, the versatility of low temperature powder coatings in adhering to a wide range of substrates including heat-sensitive materials like plastics and composites expands their application scope. This flexibility not only broadens market opportunities in sectors traditionally dominated by liquid coatings but also stimulates innovation in product formulations and application methods.

Region Insights

Geographically, the low temperature powder coatings market exhibits a diverse landscape influenced by regional economic activities, industrial development, and regulatory frameworks. North America and Europe, characterized by stringent environmental policies and a mature industrial base, are prominent regions for low temperature powder coatings adoption. These regions see significant investments in research and development, driving technological advancements and product innovations.

Asia-Pacific emerges as a burgeoning market for low temperature powder coatings, driven by rapid industrialization, urbanization, and increasing consumer demand for durable and aesthetically pleasing coatings. Countries like China, India, and Southeast Asian nations are witnessing robust growth in automotive and construction sectors, fueling demand for high-performance coatings that offer durability, corrosion resistance, and aesthetic appeal.

Low Temperature Powder Coatings Market Scope

| Report Coverage | Details |

| Market Size by 2033 | USD 197.48 Million |

| Market Size in 2023 | USD 119.86 Million |

| Market Size in 2024 | USD 125.99 Million |

| Market Growth Rate from 2024 to 2033 | CAGR of 5.12% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Resin Type, Substrate Type, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Low Temperature Powder Coatings Market Dynamics

Drivers

Several drivers underpin the growth of the low temperature powder coatings market. Environmental concerns and regulations mandating the reduction of VOC emissions from industrial processes propel the shift towards powder coatings. Low temperature variants specifically cater to industries seeking sustainable solutions without compromising on performance.

Additionally, the superior performance characteristics of low temperature powder coatings, such as excellent adhesion, scratch resistance, and durability, drive their adoption across diverse end-user industries. Automotive manufacturers, for instance, prefer these coatings for their ability to withstand harsh environmental conditions and provide a high-quality finish. Similarly, the appliance and furniture sectors benefit from the enhanced aesthetic appeal and cost-efficiency offered by low temperature powder coatings.

Opportunities

The low temperature powder coatings market presents numerous opportunities for growth and innovation. Expanding application areas beyond traditional sectors to niche markets such as aerospace, marine, and electronics create new avenues for market players. Innovations in formulation technologies, including the development of ultra-low cure powder coatings, are expected to further enhance market penetration by addressing specific industry requirements.

Moreover, partnerships and collaborations between coating manufacturers, raw material suppliers, and end-users facilitate the development of customized solutions tailored to specific performance criteria. Market players investing in research and development to improve product durability, color stability, and application efficiency are likely to capitalize on emerging opportunities in the global market.

Challenges

Despite its promising growth trajectory, the low temperature powder coatings market faces several challenges. One significant challenge is the initial investment required for upgrading existing coating lines to accommodate powder coating technologies. This capital expenditure may deter small and medium-sized enterprises from adopting low temperature powder coatings, especially in cost-sensitive markets.

Furthermore, achieving consistent coating quality and color matching across different substrates remains a technical challenge for manufacturers. Variations in substrate material, surface preparation methods, and curing conditions can affect coating performance and aesthetics, necessitating stringent quality control measures and standardized application processes.

Read Also: Biobetters Market Size to Reach USD 138.56 Billion By 2033

Low Temperature Powder Coatings Market Companies

- PPG Industries Inc.

- Axalta coating systems

- Sherwin-Williams Company

Recent Developments

- With the introduction of Interpon A3000 from AkzoNobel’s Powder Coatings division, motorcycle manufacturers can immediately begin to achieve greater cost and energy savings. The recently released product, which is the company’s first two-wheeler single layer powder coating, can assist clients in speeding up their efficiency improvements without sacrificing functionality or style. The important Indian market, which is home to well over 200 million two-wheeled vehicles, is the focus of Interpon A3000. It’s believed that over 18 million two-wheelers were sold in India in just the previous year. Also, the goods will be accessible everywhere.

- In June 2023, PPG introduced a line of electrocoat (e-coat) coatings called PPG ENVIRO-PRIME EPIC 200R coatings, which cure at a lower temperature than rival technologies. Customers benefit from the products’ reduced energy consumption and CO2 emissions at production sites, among other sustainability-related features. Garry Grant, worldwide product manager for substrate protection products at PPG Automotive Coatings, called this technology “a game-changer.” Higher oven temperatures are usually needed for conventional e-coats to cure across thicker substrates and complex assemblies, which leads to an uneven look and color variances.

Segment Covered in the Report

By Resin Type

- Polyester

- Epoxy

- Polyurethane

- Hybrid

By Substrate Type

- Metal

- Aluminum

- Steel

- Others

By End-use

- Appliances

- Furniture

- Automotive

- Electronics

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/

Blog: https://www.dailytechbulletin.com/

Blog: https://www.autoindustrybulletin.com/