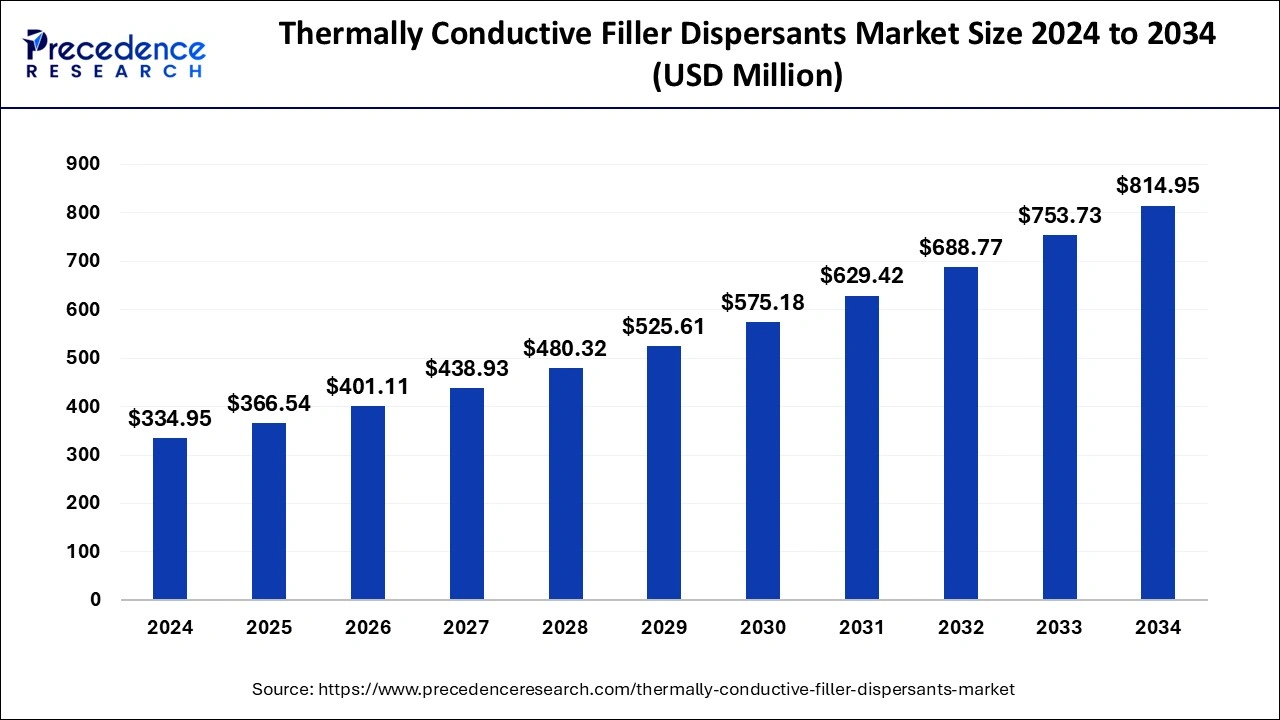

The global thermally conductive filler dispersants market size was valued at USD 306.09 million in 2023 and is predicted to reach around USD 753.73 million by 2033, expanding at a CAGR of 9.43% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market with the largest revenue share of 37% in 2023.

- North America is anticipated to grow at the fastest rate in the market over the studied period.

- By type, the metal-based fillers segment held the largest revenue share of 25% in 2023.

- By type, the ceramic-based fillers segment is expected to grow at the fastest rate in the market.

- By application, the screen printing segment has generated more than 37% of revenue share in 2023.

- By application, the dispensing segment is expected to grow at the fastest rate during the forecast period.

- By end use, the electronics & electrical segment held the largest share of the market in 2023.

- By end use, the industrial machinery segment is expected to grow at the fastest rate in the market during the projected period.

The Thermally Conductive Filler Dispersants Market is a specialized segment within the broader materials and chemicals industry, focusing on substances that enhance the thermal conductivity of various composite materials. These dispersants are used to evenly distribute thermally conductive fillers, such as metal oxides, boron nitride, and carbon-based materials, within a polymer matrix. The primary applications of these materials include electronics, automotive, aerospace, and energy storage, where efficient thermal management is crucial to ensure performance and longevity of devices and systems.

Get a Sample: https://www.precedenceresearch.com/sample/4559

Growth Factors

Several key factors are driving the growth of the Thermally Conductive Filler Dispersants Market. The increasing demand for high-performance electronics, such as smartphones, laptops, and other consumer electronics, necessitates advanced thermal management solutions to prevent overheating and ensure optimal operation. Additionally, the rise in electric vehicle (EV) adoption is propelling the need for thermally conductive materials in battery systems and power electronics. The ongoing advancements in renewable energy technologies, such as solar panels and wind turbines, also contribute to the demand for these dispersants, as efficient thermal management can significantly enhance the efficiency and lifespan of these systems.

Region Insights

Regionally, the Asia-Pacific region dominates the Thermally Conductive Filler Dispersants Market, driven by the presence of major electronics manufacturers and a robust automotive industry in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with a strong focus on technological innovation and the adoption of advanced materials in various industries. The increasing investments in research and development, along with supportive government policies promoting sustainable energy and electric vehicles, further bolster market growth in these regions.

Thermally Conductive Filler Dispersants Market Trends

- Rising Demand in Electronics and Electrical Industry: With the rapid growth of the electronics and electrical industry, the demand for thermally conductive materials has surged. These materials are essential for managing heat in electronic devices, ensuring their efficiency and longevity. Dispersants play a critical role in enhancing the thermal conductivity of fillers used in these applications.

- Advancements in Material Science: Innovations in material science have led to the development of advanced dispersants that offer better compatibility with various fillers and substrates. These new dispersants improve the dispersion quality, leading to enhanced thermal conductivity and overall performance of the composites.

- Growing Applications in Automotive Industry: The automotive industry is increasingly adopting thermally conductive materials for applications such as battery thermal management in electric vehicles (EVs) and heat dissipation in electronic control units (ECUs). This trend is driving the demand for high-performance thermally conductive filler dispersants.

- Shift Towards Sustainable and Eco-friendly Solutions: There is a growing emphasis on sustainability and environmental impact. Manufacturers are developing eco-friendly dispersants that are non-toxic and biodegradable, catering to the increasing regulatory and consumer demands for green products.

- Increased Focus on Research and Development: Companies are investing significantly in research and development to create dispersants that offer superior performance. This includes improving the thermal conductivity, mechanical properties, and ease of processing of thermally conductive composites.

- Expansion in Emerging Markets: The expansion of the electronics, automotive, and industrial sectors in emerging markets like China, India, and Southeast Asia is creating new opportunities for the thermally conductive filler dispersants market. These regions are witnessing significant industrial growth, leading to increased demand for high-performance materials.

Thermally Conductive Filler Dispersants Market Scope

| Report Coverage | Details |

| Market Size by 2033 | USD 753.73 Million |

| Market Size in 2023 | USD 306.09 Million |

| Market Size in 2024 | USD 334.95 Million |

| Market Growth Rate from 2024 to 2033 | CAGR of 9.43% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Type, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Thermally Conductive Filler Dispersants Market Dynamics

Drivers

The primary drivers of the Thermally Conductive Filler Dispersants Market include the rapid technological advancements in the electronics and automotive sectors, which require efficient thermal management solutions. The increasing focus on renewable energy and the growing adoption of electric vehicles are also significant drivers, as they necessitate advanced thermal management materials to enhance performance and safety. Additionally, the rising awareness of the benefits of thermally conductive materials in improving energy efficiency and reducing operational costs is driving market growth.

Opportunities

The market presents several opportunities for growth and innovation. The increasing demand for miniaturized and high-performance electronic devices offers significant potential for the development of advanced thermally conductive filler dispersants. The growing focus on sustainable and green technologies provides opportunities for developing eco-friendly dispersants. Moreover, the expanding applications of these materials in emerging industries, such as wearable technology and 5G infrastructure, present new growth avenues for market players.

Challenges

Despite the promising growth prospects, the Thermally Conductive Filler Dispersants Market faces several challenges. The high cost of advanced dispersants and the complexity of manufacturing processes can hinder market growth, especially for small and medium-sized enterprises. Ensuring uniform dispersion and compatibility of fillers with various polymer matrices remains a technical challenge. Additionally, stringent regulatory requirements and environmental concerns regarding the production and disposal of these materials can pose significant hurdles for market players.

Read Also: Stem Cell Banking Market Size to Reach USD 24.68 Bn by 2033

Thermally Conductive Filler Dispersants Market Companies

- BYK

- Shin-Etsu Chemical

- Dow Chemical Company

- JNC Corporation

- Momentive Performance Materials

- Kusumoto Chemicals

- Evonik

- Croda International

- Lubrizol

Recent Development

- In April 2022, Shin-Etsu Co. Ltd. developed the TC-BGI Series, a thermal interface silicone rubber sheet, for use in electric vehicle components as high-voltage device technology advances. This sheet is a hard, thermal-interface silicone rubber that offers good levels of voltage resistance and heat dissipation.

Segment Covered in the Report

By Type

- Metal-based Fillers

- Ceramic-based Fillers

- Carbon-based Fillers

By Application

- Screen Printing

- Dispensing

- Extrusion

- Spray Coating

- Syringe Dispensing

By End-use

- Electronic and Electrical

- Automotive

- Aerospace and Defense

- Industrial Machinery

- Telecommunication

- Healthcare & Medical Devices

- Consumer Goods

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/

Blog: https://www.dailytechbulletin.com/

Blog: https://www.autoindustrybulletin.com/