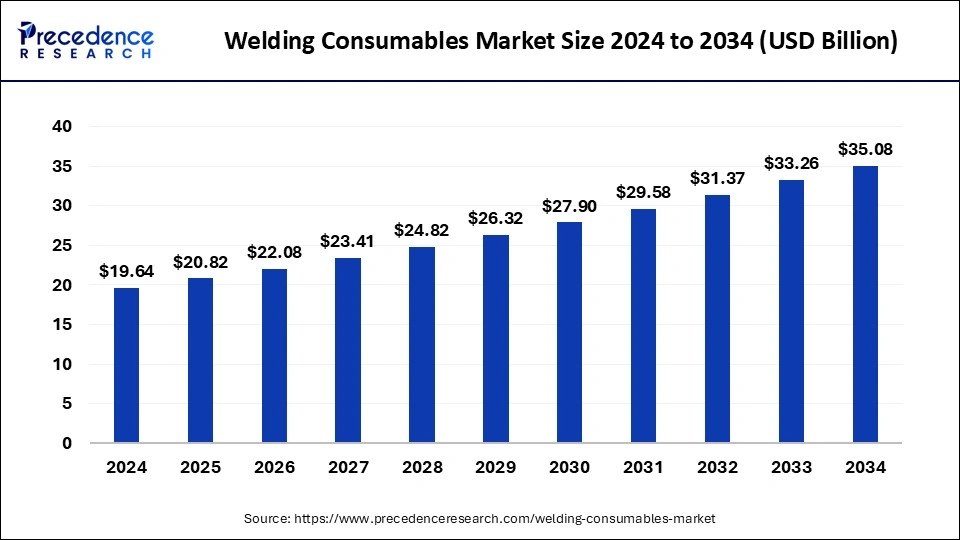

The global welding consumables market size was estimated at USD 18.52 billion in 2023 and is predicted to reach around USD 33.26 billion by 2033, growing at a CAGR of 6.03% from 2024 to 2033.

Key Points

- The North America welding consumables market size accounted for USD 6.67 billion in 2023 and is expected to attain around USD 12.14 billion by 2033, poised to grow at a CAGR of 6.17% between 2024 and 2033.

- North America has held a significant revenue share of 36% in 2023.

- Asia Pacific is expected to witness growth at the fastest rate over the projected period.

- By type, the electrodes segment dominated the market in 2023.

- By type, flux segment is expected to gain a significant share of the market over the forecast period.

- By welding technique, the arc welding segment dominated the global market in 2023.

- By welding technique, the resistance wedding segment is expected to grow rapidly during the forecast period.

The welding consumables market encompasses a wide range of products essential for various welding processes. Welding consumables include electrodes, filler metals, fluxes, and gases, which play a crucial role in ensuring the integrity, strength, and durability of welded joints. These consumables are integral to industries such as construction, automotive, shipbuilding, and aerospace, where welding is a fundamental process.

In recent years, the welding consumables market has witnessed significant growth driven by rapid industrialization and urbanization, particularly in emerging economies. The demand for high-quality infrastructure, advancements in manufacturing technologies, and increasing adoption of automation in welding processes are key factors contributing to the market expansion. Moreover, the development of innovative welding consumables that enhance efficiency and reduce operational costs has further fueled market growth.

Get a Sample: https://www.precedenceresearch.com/sample/4412

Growth Factors

Several factors are driving the growth of the welding consumables market. Firstly, the booming construction industry is a major contributor. With increasing investments in infrastructure projects such as bridges, highways, and commercial buildings, the demand for welding consumables has surged. Additionally, the rise in residential construction activities, driven by urbanization and population growth, is further propelling the market.

Secondly, the automotive industry plays a significant role in the market expansion. The growing demand for automobiles, coupled with advancements in automotive manufacturing techniques, has increased the need for welding consumables. The trend towards lightweight vehicles, which require advanced welding processes, is also contributing to the market growth.

Furthermore, the aerospace industry is witnessing a surge in demand for welding consumables. The production of aircraft and spacecraft involves intricate welding processes that require high-quality consumables to ensure the structural integrity and safety of the final products. The increasing focus on space exploration and defense projects is further boosting the demand for welding consumables.

Another critical growth factor is the rising adoption of automation in welding processes. Automated welding systems offer higher precision, speed, and consistency, reducing the risk of human error. This trend is particularly prominent in industries such as automotive and manufacturing, where efficiency and productivity are paramount. The development of advanced welding consumables designed specifically for automated systems is further driving market growth.

Region Insights

The welding consumables market exhibits significant regional variations, driven by factors such as industrialization, economic development, and technological advancements.

North America

In North America, the market is characterized by a high demand for welding consumables from the automotive and construction industries. The presence of leading automotive manufacturers and a robust construction sector contribute to the market growth. Additionally, the region’s focus on infrastructure development and renovation projects is driving the demand for welding consumables. The United States, in particular, is a major contributor to the market due to its advanced manufacturing sector and significant investments in infrastructure.

Europe

Europe is another prominent market for welding consumables, with countries such as Germany, France, and the United Kingdom leading the demand. The region’s strong industrial base, coupled with advancements in manufacturing technologies, is fueling the market growth. Moreover, Europe’s focus on renewable energy projects, such as wind and solar power, is increasing the demand for welding consumables used in the fabrication of energy infrastructure.

Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in the welding consumables market, driven by extensive industrialization and urbanization. Countries such as China, India, and Japan are key contributors to the market due to their expanding construction and automotive industries. The region’s increasing investments in infrastructure projects, including bridges, highways, and railways, are further propelling the market. Additionally, the growing aerospace and defense sectors in Asia-Pacific are boosting the demand for high-quality welding consumables.

Latin America

In Latin America, the welding consumables market is driven by the construction and oil & gas industries. Countries such as Brazil and Mexico are witnessing significant growth in infrastructure development, leading to increased demand for welding consumables. The region’s focus on energy projects, including oil refineries and pipelines, is also contributing to the market expansion.

Middle East & Africa

The Middle East & Africa region is characterized by a growing demand for welding consumables from the oil & gas and construction sectors. The region’s significant investments in infrastructure projects, including airports, commercial buildings, and residential complexes, are driving the market growth. Additionally, the focus on expanding oil & gas exploration and production activities is boosting the demand for welding consumables in the region.

Welding Consumables Market Scope

| Report Coverage | Details |

| Welding Consumables Market Size in 2023 | USD 18.52 Billion |

| Welding Consumables Market Size in 2024 | USD 19.64 Billion |

| Welding Consumables Market Size by 2033 | USD 33.26 Billion |

| Welding Consumables Market Growth Rate | CAGR of 6.03% from 2024 to 2033 |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Type, Welding Technique, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Drivers

Several key drivers are propelling the welding consumables market:

Infrastructure Development

The increasing investments in infrastructure development, particularly in emerging economies, are driving the demand for welding consumables. The construction of bridges, highways, airports, and commercial buildings requires extensive welding processes, fueling the market growth.

Industrialization and Urbanization

Rapid industrialization and urbanization are major drivers of the welding consumables market. The expansion of manufacturing facilities and the rise in urban construction activities are increasing the demand for welding consumables across various industries.

Automotive Industry Growth

The automotive industry’s growth is significantly contributing to the market. The production of automobiles involves numerous welding processes, requiring high-quality consumables to ensure the strength and safety of the vehicles. Additionally, the trend towards lightweight vehicles is driving the demand for advanced welding consumables.

Technological Advancements

Advancements in welding technologies and the development of innovative welding consumables are major market drivers. The introduction of automated welding systems and the use of advanced materials in consumables are enhancing welding efficiency and reducing operational costs, driving market growth.

Renewable Energy Projects

The increasing focus on renewable energy projects, such as wind and solar power, is driving the demand for welding consumables. The fabrication of energy infrastructure, including wind turbines and solar panels, requires specialized welding consumables, contributing to the market expansion.

Opportunities

The welding consumables market offers several opportunities for growth and expansion:

Emerging Markets

The growing industrialization and urbanization in emerging markets, particularly in Asia-Pacific and Latin America, present significant opportunities for the welding consumables market. The increasing investments in infrastructure projects and the expansion of manufacturing facilities in these regions are expected to drive market growth.

Technological Innovations

The development of new and innovative welding consumables presents significant opportunities for market players. The focus on creating consumables that enhance welding efficiency, reduce costs, and improve the quality of welded joints is driving research and development activities in the industry.

Automation in Welding

The increasing adoption of automation in welding processes presents opportunities for market growth. Automated welding systems offer higher precision, speed, and consistency, reducing the risk of human error. The development of advanced welding consumables designed specifically for automated systems is expected to drive market expansion.

Renewable Energy Sector

The growing focus on renewable energy projects offers significant opportunities for the welding consumables market. The fabrication of renewable energy infrastructure, including wind turbines and solar panels, requires specialized welding consumables. The increasing investments in renewable energy projects are expected to boost the demand for welding consumables.

Challenges

Despite the growth prospects, the welding consumables market faces several challenges:

Fluctuating Raw Material Prices

The prices of raw materials used in the production of welding consumables, such as metals and alloys, are subject to fluctuations. The volatility in raw material prices can impact the production costs and profit margins of market players, posing a challenge to the market growth.

Environmental Regulations

Stringent environmental regulations related to welding processes and the use of certain materials in welding consumables pose a challenge to the market. The need to comply with these regulations can increase the production costs and affect the availability of certain consumables in the market.

Skilled Labor Shortage

The shortage of skilled labor in the welding industry is a significant challenge. The welding process requires skilled and experienced workers to ensure the quality and safety of welded joints. The shortage of skilled welders can impact the efficiency and productivity of welding processes, posing a challenge to the market growth.

Technological Complexity

The increasing complexity of welding technologies and processes can pose a challenge to market growth. The need for continuous training and upskilling of workers to operate advanced welding systems and use innovative consumables can increase the operational costs for companies.

Read Also: Sinus Dilation Devices Market Size to Reach USD 7.60 Bn by 2033

Welding Consumables Market Recent Developments

- In February 2023, Miller Electric Mfg. LLC, which is considered one of the prominent manufacturers of welding equipment and consumable products, has recently unveiled its Copilot collaborative welding system. This system will enable welders to achieve better quality of welding and optimize the use of consumables enabling the users to meet augmented demand.

- In February 2022, Miller Electric Mfg., which offers arc welding equipment under its brand name Miller, has recently announced that the company is venturing into a collaboration with NCCER (National Center for Construction Education & Research). The collaboration efforts will provide NCCER welding levels 1 and 2 to integrate its augmented reality welding system.

- In May 2022, Lincoln Electric, engaged in developing, manufacturing, and supplying welding equipment and consumables across diverse geographies, has increased diversity in its existing product portfolio by offering hyperfill solutions into its Flux-Cored wire applications.

Welding Consumables Market Companies

- voestalpine AG

- Colfax Corporation

- The Lincoln Electric Company

- Air Liquide

- Hyundai Welding Co., Ltd.

- Obara Corporation

- Panasonic Corporation

- Illinois Tool Works Inc.

- Denyo Co., Ltd.

- Fronius International GmbH

- Tianjin Bridge Welding Materials Co., Ltd.

- Kemppi Oy

- Arcon Welding Equipment

Segments Covered in the Report

By Type

- Electrodes

- Flux

- Shielding Gas

- Filler Metals

- Others

By Welding Technique

- Arc Welding

- Resistance Welding

- Oxy-Fuel Welding

- Laser-Beam Welding

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.dailytechbulletin.com/

Blog: https://www.autoindustrybulletin.com/